Good, Better, Best: Optimizing CO2 Dispersion for Maximum Plant Growth

In controlled environment agriculture (CEA), efficient CO2 enrichment is a game-changer for improving photosynthesis, accelerating plant growth, and maximizing yields. However, simply adding CO2 to a grow room isn’t enough—how CO2 is dispersed plays a crucial role in achieving optimal results. This guide explores the good, better, and best methods of CO2 dispersion, helping cultivators in commercial cultivation facilities choose the right indoor farming CO2 system for their needs.

The Importance of Effective CO2 Dispersion

CO2 is heavier than air, meaning it tends to settle near the ground rather than distribute evenly throughout the grow space. Without proper dispersion, plants may not receive consistent CO2 plant growth benefits, leading to inefficiencies and wasted resources. The right dispersion method ensures uniform CO2 delivery, maximizing CO2 optimization and overall plant productivity.

Good: CO2 Injection into HVAC Supply Air Ducting

One of the most common and cost-effective CO2 dispersion methods is injecting CO2 directly into the HVAC supply air ducting. This approach allows CO2 to mix with conditioned air and distribute throughout the grow room.

Pros:

Low-cost solution for growers just starting with CO2 enrichment.

Utilizes existing HVAC infrastructure, minimizing additional equipment costs.

Helps distribute CO2 evenly, but with limited precision.

Cons:

CO2 levels may vary across the grow space, leading to inefficiencies.

Potential CO2 stratification, with higher concentrations at floor level.

Less targeted CO2 delivery to the plants' active growth zones.

Best suited for small to mid-size commercial cultivation facilities looking for a simple and budget-friendly way to implement CO2 optimization.

Better: Rack-Mounted Airflow Systems for CO2 Distribution

A more effective way to disperse CO2 is through a rack-mounted airflow system, such as the Pipp Racking Vertical Airflow System (VAS). This method delivers CO2 from the top of the plant canopy, ensuring a more uniform distribution while reducing stratification.

Pros:

Provides better CO2 penetration into the canopy compared to HVAC injection.

Improves airflow, reducing microclimates and promoting consistent plant development.

Works well for vertical farming and multi-tiered grow spaces.

Cons:

Requires additional installation and equipment.

CO2 may still dissipate before reaching lower portions of the canopy.

A great choice for mid-to-large commercial cultivation facilities aiming to improve CO2 plant growth outcomes without major structural modifications.

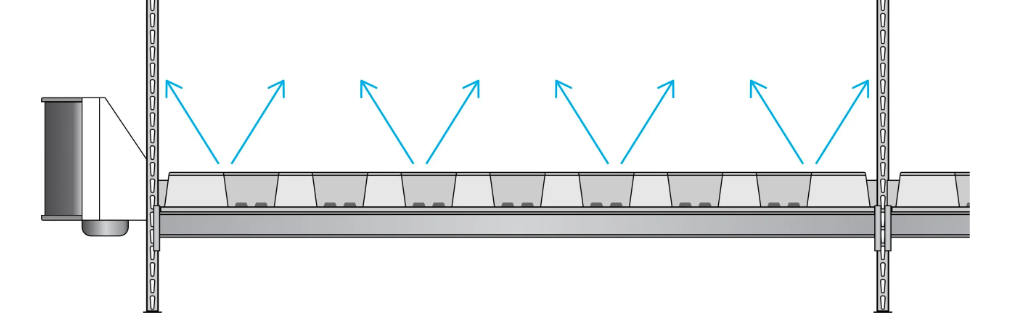

Best: Under-Canopy Airflow Systems for Precision CO2 Delivery

For the highest level of CO2 optimization, under-canopy airflow systems like the Dual Draft System deliver CO2 directly within the plant canopy. By injecting CO2 from below, this method ensures that plants receive enriched air precisely where they need it most—at the stomatal openings on the undersides of their leaves.

Pros:

Maximizes CO2 enrichment efficiency by placing CO2 exactly where plants absorb it.

Eliminates CO2 stratification and ensures even distribution across all plants.

Improves overall air circulation, reducing mold and disease risks.

Cons:

Requires an upfront investment in specialized equipment.

Best suited for large-scale indoor farming CO2 systems with dedicated infrastructure.

The ultimate solution for growers who want to optimize CO2 plant growth while maintaining the most efficient and cost-effective use of bulk CO2 supply.

Conclusion

Maximizing plant health and yield potential requires more than just CO2 enrichment—it demands precise and strategic CO2 dispersion. From HVAC injection to under-canopy airflow systems, choosing the right method ensures better CO2 optimization, efficient bulk CO2 supply usage, and healthier plants.

For growers looking to take their commercial cultivation facility to the next level, investing in the best CO2 plant growth solutions will pay dividends in both yield and quality.

Visit PlantCO2.com for a CO2 Design for your facility